In the world of material processing, the quest for efficiency, reliability, and versatility often leads manufacturers and agricultural producers to seek innovative solutions. One such solution that stands out in the market for its ability to handle a wide range of materials is the double roller extrusion granulator. This machine, designed to press and compact materials into granules, has become increasingly popular due to its effectiveness in optimizing the granulation process.

What Raw Materials Can Be Optimally Processed Through Dry Granulation Technology?

Dry granulation technology, as utilized by double roller extrusion granulators, offers a unique approach to material processing. This method does not require the addition of liquids, making it an ideal choice for materials that are sensitive to moisture or where drying would be impractical. But what types of raw materials stand to benefit the most from this process?

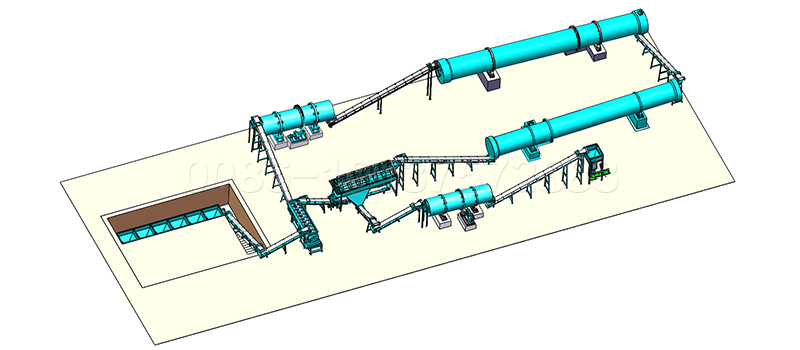

1TPH Model Double Roller Press Granulator

The Ideal Raw Materials for Double Roller Press Granulation

- Compost: Compost, rich in organic matter, can be challenging to granulate due to its variable moisture content. However, the double roller extrusion granulator can effectively compact compost into uniform granules, enhancing its market value and ease of application.

- Gypsum: Gypsum’s powdery nature makes it difficult to handle and apply. Through the compacting capabilities of the double roller granulator, gypsum can be transformed into easy-to-handle granules, improving its utility in construction and agriculture.

- Livestock Manure: The conversion of livestock manure into granulated form through dry granulation technology not only facilitates easier handling and transportation but also reduces odor and improves nutrient availability.

- Bio-Sludge: Processing bio-sludge into granular form enhances its disposal options and potential use as a soil conditioner. The roller extrusion granulator can effectively handle the unique properties of bio-sludge, offering an environmentally friendly solution to waste management.

raw material for roller compact granulation

Yushunxin’s Double Roller Extrusion Granulator: A Model of Versatility and Efficiency

As the industry seeks machines that can handle a diverse range of materials, Yushunxin’s double roller compact pelletizer emerges as a leading choice. Boasting a design that accommodates the peculiarities of various materials, from organic waste to mineral powders, this machine demonstrates exceptional versatility. Its capability to process materials without the need for liquid binders sets it apart, allowing users to achieve optimal granulation results while maintaining the integrity of the processed materials.

Moreover, the granulator’s efficiency in converting raw materials into uniform, market-ready granules underscores its value in both agricultural production and beyond. The adaptability of Yushunxin’s machinery to a broad spectrum of materials underscores the potential for applications not just in agriculture but also in sectors like waste management, recycling, and bioenergy.

2T-H Roller Compact Granulator for NPK Pellets

Conclusion

The double roller extrusion granulator represents a pivotal advancement in material processing technology. Its ability to handle a wide array of raw materials, from compost and gypsum to livestock manure and bio-sludge, highlights its relevance in today’s diverse industrial landscape. With models like YSX’s extruder granulator leading the way, the future of material processing looks promising. This machinery not only optimizes the granulation process but also opens new avenues for sustainable material management across various industries. Thus, you can visit this website for more details: https://www.extruder-granulator.com/double-roller-extruder-granulator/