El sector agrícola enfrenta el desafío constante de producir de manera sostenible y eficiente. Dentro de este contexto, la producción de abonos orgánicos representa una solución ecológica que promueve la fertilidad del suelo y el crecimiento saludable de los cultivos. Un aspecto crucial en la creación de estos fertilizantes es el proceso de mezcla, donde la uniformidad y la calidad del producto son esenciales para su eficacia.

La mezcla perfecta: Un vistazo a nuestros equipos

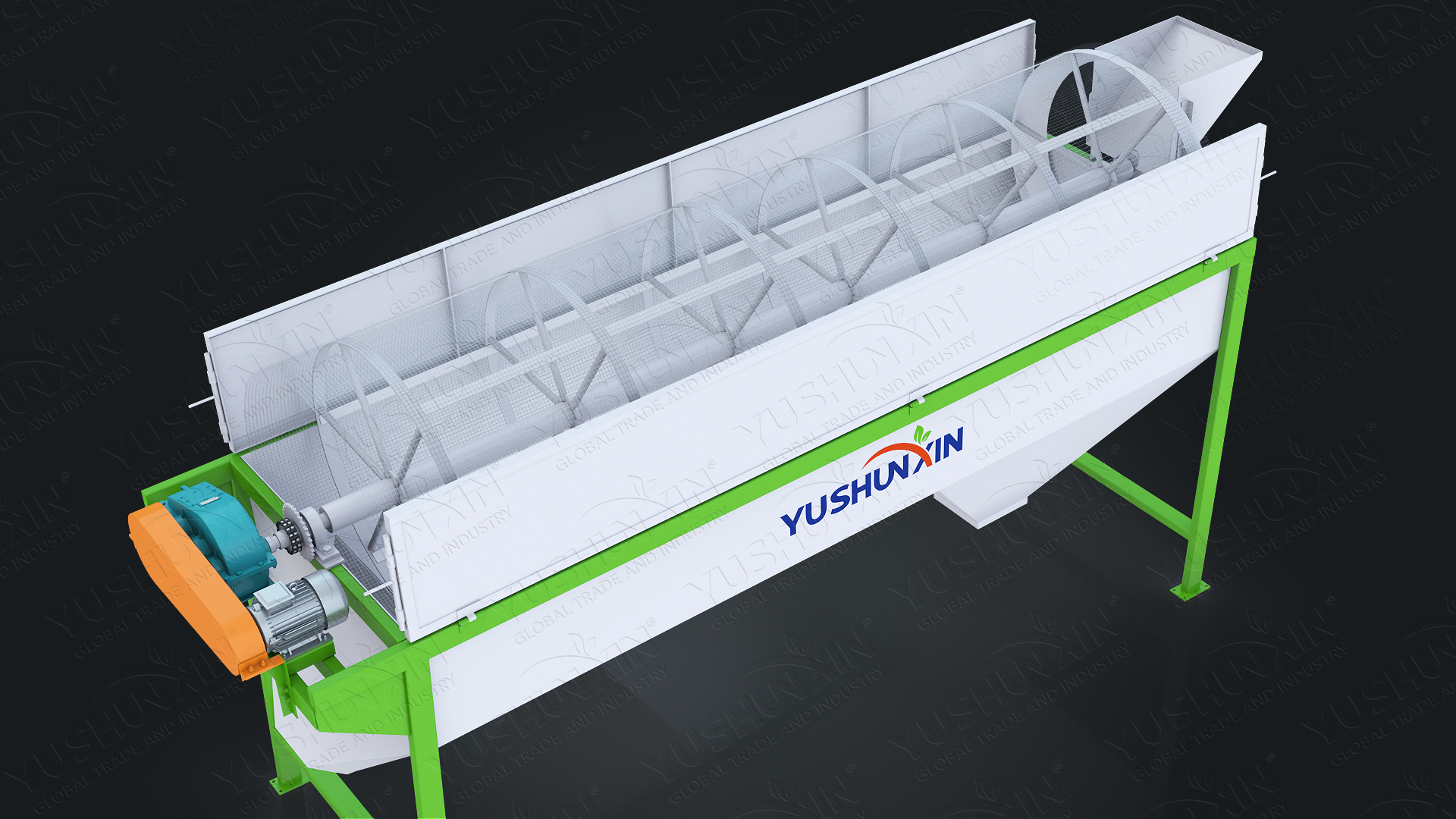

Mezcladora Horizontal: Eficacia en Cada Giro

La mezcladora horizontal es el corazón de nuestro catálogo de equipos. Con su innovador sistema de rotores opuestos, garantiza una mezcla homogénea, promoviendo una distribución equitativa de nutrientes en cada lote de fertilizante. Ofrecemos tres modelos que se ajustan a distintas escalas de producción, con capacidades que oscilan entre 2-3t/h y 10-15t/h.

Mezcladora Horizontal

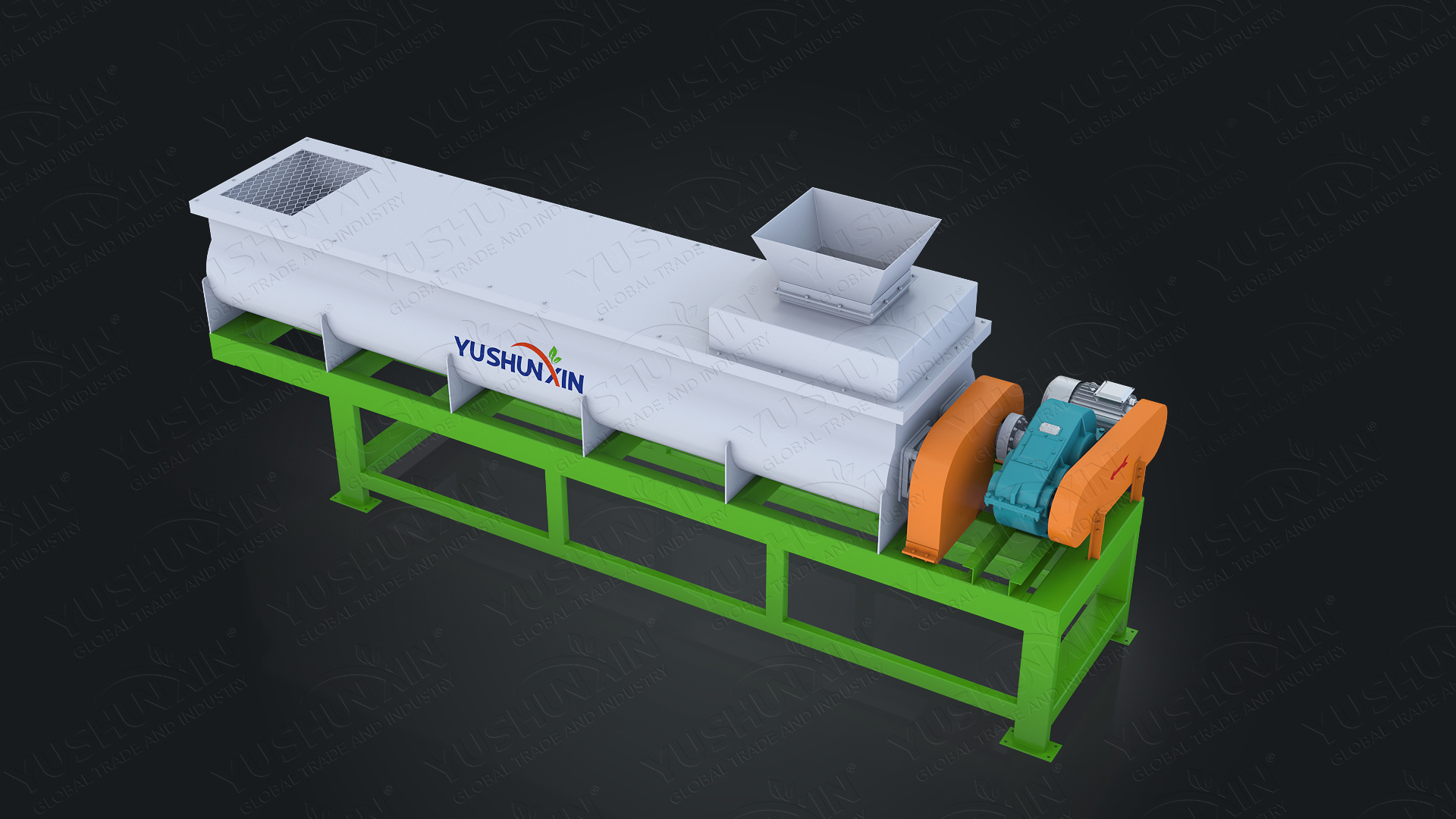

Mezclador Horizontal de Doble (o Solo) Eje: Potencia y Versatilidad

Para aquellos que buscan eficiencia después de la dosificación, presentamos nuestros mezcladores de eje simple y doble. Ambos están diseñados para manejar una amplia gama de materiales, con modelos que soportan desde 3-5t/h hasta 10-15t/h. La diferencia entre un eje y doble eje radica principalmente en la potencia y la acción de las cuchillas giratorias.

mezclador horizontal de doble eje

Mezcladora de Tambor de Abonos Orgánicos: Producción a Gran Escala

Pensando en los clientes que producen a gran escala, ofrecemos la mezcladora de tambor giratorio con capacidad de hasta 30-40 toneladas por hora. Con la opción de personalizar el revestimiento para proteger contra la corrosión, este equipo es una inversión segura para un rendimiento duradero.

Mezclador Fertilizante BB de Tambor

Mezcladora de Disco: Tecnología Especializada

La mezcladora de disco es nuestra solución especializada para la producción de abonos orgánicos. Con una estructura de acero al carbono y cuchillas de aleación resistente al desgaste, este equipo promete durabilidad y mezcla eficaz. Ofrecemos cinco modelos que se acomodan a distintas necesidades, con capacidades que varían desde 2-4t/h hasta 8-12t/h.

Mezcladora de Disco

Escenarios de Aplicación:

Nuestros equipos de mezcla son versátiles y se adaptan a varios escenarios. Las mezcladoras horizontales y de eje pueden usarse en diversas industrias, incluyendo la producción de abonos orgánicos desde excrementos animales hasta aplicaciones en química y construcción. La mezcladora de tambor es ideal para fertilizantes BB y compuestos, mientras que la mezcladora de disco se destaca en la producción orgánica exclusivamente.

Servicios Adicionales:

Entendemos que cada proyecto es único. Por eso, ofrecemos servicios personalizados de diseño, asesoramiento en la selección de equipos y asistencia posventa integral. Desde la garantía de un año hasta la adquisición de repuestos al precio de fábrica y el soporte continuo, estamos comprometidos a garantizar que su equipo funcione sin problemas.

En la búsqueda de soluciones de mezcla para fertilizantes orgánicos, nuestro objetivo es proporcionar equipos que no solo cumplan con sus expectativas de producción sino que también reflejen nuestro compromiso con la sustentabilidad y la eficiencia. Nos enorgullecemos de ser sus aliados en este camino hacia una agricultura más verde y productiva. Si está listo para llevar su producción al siguiente nivel, ¡hablemos!