How to Use Disc Granulation Machine to Make Zeolite Pellets

Introduction to Zeolite Pelletization

Zeolite, a microporous, aluminosilicate mineral, is widely used in various industries for its adsorption, ion exchange, and catalytic properties. The pelletization of zeolite powder can improve its usability, handling, and performance in different applications. A popular method to achieve this is via disc granulation, a process that converts fine powders into larger, rounded pellets.

Understanding Disc Granulation Machines

Disc granulation machines, also known as pan granulators, are circular pans with a nearly flat surface and an adjustable angle of inclination. They are designed to agglomerate powdered materials into granules using a combination of rotational motion and force. The machine’s simplicity and effectiveness in producing uniform-sized pellets make it suitable for the pelletization of zeolite. If you are interested in other zeolite pellets granulating machine, we can also offer for you.

Preparing for Granulation

Before starting the granulation process, ensure that the zeolite powder is of appropriate particle size and moisture content. The powder should be fine enough to allow for proper agglomeration and should typically have a moisture content between 30-40% to facilitate the formation of pellets.

Setting Up the Disc Granulator

- Adjusting the Disc Angle: Set the disc angle between 40 to 60 degrees, depending on the desired pellet size and the material properties.

- Setting the Rotational Speed: The disc speed should be adjusted to create optimal tumbling action, allowing the material to roll and grow into pellets.

- Preparing the Disc Surface: A layer of powder is spread on the disc surface to prevent sticking and to initiate the granulation process.

The Granulation Process

- Feeding the Material: Start feeding the zeolite powder into the disc granulator while ensuring an even distribution across the disc.

- Pellet Growth: As the pan rotates, the material rolls and collides, picking up more powder and growing into pellets. Water can be sprayed onto the mixture if additional moisture is needed.

- Pellet Sizing: Smaller particles stick to larger ones, and the continuous rolling motion helps to round off the pellets, enforcing a uniform size.

- Processing Duration: The process continues until the desired pellet size is achieved, which usually takes several minutes.

Post-Granulation Steps

- Drying the Pellets: Once the desired pellet size is obtained, the pellets are transferred to a drying apparatus to reduce the moisture content and harden the surface.

- Cooling and Screening: After drying, the pellets are cooled and then screened to separate the properly sized pellets from the undersized or oversized ones.

- Recycling Overs and Fines: The separated fines and oversized pellets are recycled back into the system to improve yield and reduce waste.

Maintenance and Troubleshooting

Regular maintenance of the disc granulator is essential to ensure efficient and uninterrupted operation. This involves cleaning the machine, checking for wear and tear, and lubricating moving parts. If issues arise, such as uneven pellet sizes or poor pellet formation, adjustments may be needed in moisture content, disc angle, or rotational speed.

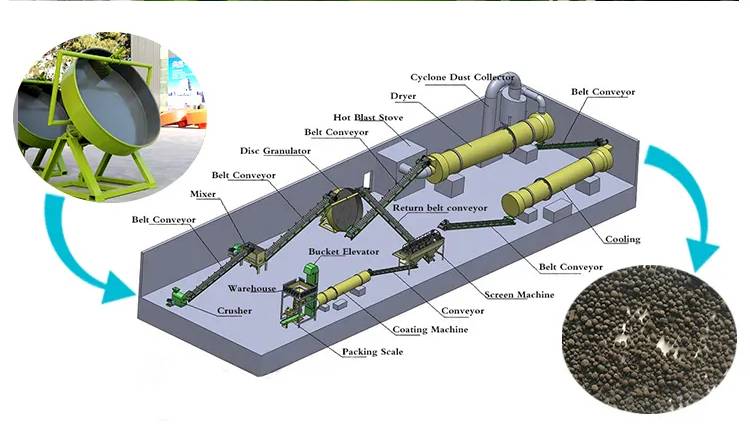

Conclusion Disc granulation is an effective and widely used method for producing zeolite pellets. By following the proper steps and maintaining the equipment, one can achieve high-quality pellets that meet industry standards. With optimal settings and operation, disc granulation provides a reliable solution for enhancing the properties and handling of zeolite materials. And if you want to setup a zeolite disc granulation plant, we can provide you with the best solution.

disc zeolite pellets making plant