Biochar organic fertilizer manufacture

In recent years, the demand for sustainable and environmentally friendly agricultural practices has led to the emergence of biochar organic fertilizer making. This revolutionary approach combines the benefits of organic matter with the carbon-enhancing properties of biochar, resulting in a highly effective and eco-conscious fertilizer. In this blog, there are manufacturing processes of two kinds of Biochar Organic Fertilizer – powder and granulation lines. You can click here for details.

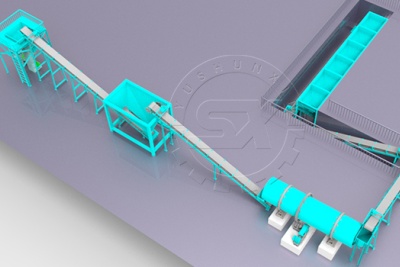

Powder Fertilizer Making Line:

Biochar organic fertilizer production line

The powder fertilizer production line follows a sequence of steps, guaranteeing optimal nutrient content and uniformity throughout. And it has the advantage of being a simple, quick and inexpensive process. Here’s the key processes involved:

Composting:

The first step in the powder fertilizer production line is the composting process. Organic materials such as crop residue, animal manure, and food waste are carefully selected and mixed. The mixture undergoes a controlled decomposition process, allowing beneficial microorganisms to break down complex organic compounds into simpler nutrients.

Crushing:

Once the composting process is complete, the resulting mixture is crushed using specialized equipment. The purpose of this step is to ensure the uniformity of the particle size, facilitating subsequent processing and application.

Mixing:

The crushed materials are thoroughly mixed to guarantee a homogenous blend of nutrients. This step plays a crucial role in biochar organic fertilizer making ensuring consistent fertilizer quality and nutrient distribution.

Screening and packaging:

After the mixing process, the material is screened to remove any impurities or oversized particles. This ensures a high-quality end product with a uniform particle size distribution. And the final step in the powder fertilizer making line is packaging. The processed biochar organic fertilizer is carefully weighed, packed, and sealed to maintain its freshness and extend its shelf life. Proper packaging also facilitates convenient storage and transportation.

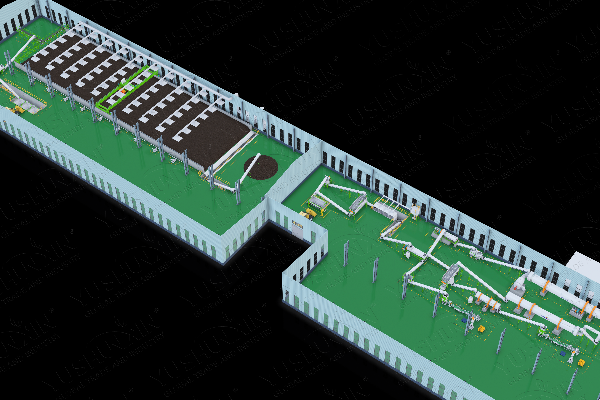

Granulation Line:

The granulation line provides an alternative approach to produce Biochar Organic Fertilizer, which offers additional advantages such as fertilizer particles are rounder and fuller, making them easier to store and easier to transport. Here are the key stages involved:

Composting and Crushing:

Similar to the powder fertilizer production line, composting is the first step in the production of charcoal organic fertilizer in a pelletizing line. Following composting, the material is crushed into smaller particles, ensuring a consistent feedstock for the granulation process.

Granulating:

Granulation is a key step in the production of granulated biochar organic fertilizer production. In this process, the crushed material is transformed into granules through the use of specialized machinery. The granulation process enhances the structural integrity of the fertilizer, allowing for controlled nutrient release and improved soil penetration.

Mixingand screening:

The granules are thoroughly mixed to guarantee a consistent nutrient distribution and fertilizer quality. Similar to the powder fertilizer making line, the granules are screened to remove any impurities or oversized particles, ensuring a high-quality end product.

Drying and Cooling:

After screening, the granules are dried and cooled to a suitable moisture content. And cooling step ensures the long-term stability and preservation of the granulated organic fertilizer.

Packaging:

Finally, the granulated fertilizer is carefully packaged, preserving its granular structure and making it easy to handle, store, and apply.

Conclusion:

Biochar Organic Fertilizer has gained significant attention in the agricultural sector due to its proven benefits in enhancing crop productivity and sustainability. The two distinct production lines, powder and granulation, offer designers the flexibility to manufacture high-quality organic fertilizers tailored to specific agricultural needs. Understanding the manufacturing processes involved is crucial for appreciating the value and effectiveness of biochar organic fertilizer manufacture in promoting sustainable agriculture. If you want to know more, you can view this page: https://www.charbasedfertilizermachine.com/product/organic-fertilizer-manufacturing/.