Benefits of Dry Granulation Equipment for Fertilizer Pellets Making

Dry granulation equipment is a critical component in the production of fertilizer pellets, offering a range of benefits that enhance the efficiency, cost-effectiveness, and quality of the final product. The process of dry granulation involves the agglomeration of fine powder into larger, denser granules without the need for liquid binders, making it a preferred method in the fertilizer production project for various reasons.

1. No Need for Drying Processes:

One of the primary advantages of dry granulation is that it eliminates the need for drying processes, which are energy-intensive and costly. Since no liquid is added during granulation, the final granules do not contain excess moisture that needs to be removed, thus saving on energy consumption and reducing the overall production costs of fertilizer manufacturing.

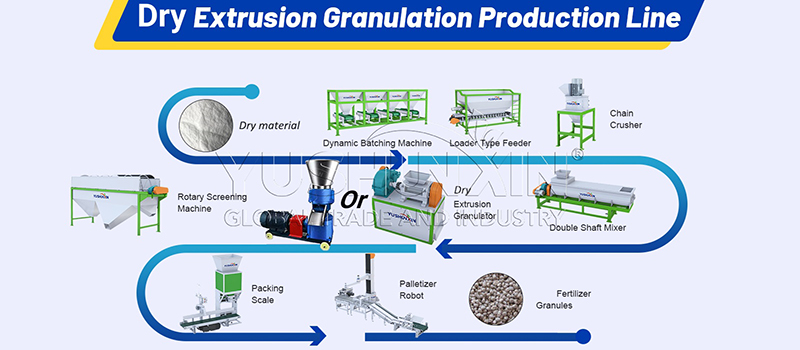

Fertilizer dry granulation process

2. Energy Efficiency:

Dry granulation equipment operates without the additional energy requirements that come with wet granulation methods, such as those needed for drying and cooling. This results in significant energy savings, reducing the carbon footprint of the production process and contributing to more sustainable production practices.

3. Cost Savings:

The reduction in energy usage translates directly into cost savings. Additionally, the absence of liquid binders and the associated drying equipment reduces the initial investment and maintenance costs for the fertilizer granule manufacturing facility.

4. Improved Product Stability:

Dry granulated fertilizers are more stable and less susceptible to degradation compared to those produced by wet granulation. The lack of moisture ensures a longer shelf life and prevents the breakdown of nutrients over time, maintaining the efficacy of the fertilizer.

5. Ease of Handling and Storage:

Dry granulation machine produces dense, uniformly sized pellets that are easier to handle, package, and store. These pellets are less likely to produce dust, reducing product loss during handling and transportation. The improved flow characteristics also make automated packaging processes more reliable and efficient.

6. Versatility in Raw Materials:

Dry granulation equipment can handle a variety of raw materials, including those that are heat-sensitive or that may react negatively to moisture like urea. This allows for a broader range of fertilizer formulations to be produced using the same equipment.

7. Controlled Release:

The density and hardness of the granules can be adjusted during the dry granulation process, allowing for the production of controlled-release fertilizers. These types of fertilizers release nutrients slowly over time, improving nutrient uptake by plants and minimizing nutrient leaching into the environment.

8. Environmental Benefits:

With no wastewater generated from the use of liquid binders, dry granulation is a more environmentally friendly process. This advantage aligns with the increasing regulatory and consumer demand for more sustainable production methods in the agriculture industry.

9.Streamlined Production Process:

The simplicity of the dry granulation process makes it easier to control and streamline. The reduction in process steps and the ease of integrating dry granulation equipment into existing production lines can enhance overall efficiency and productivity.Click here to learn more

10. Better Product Quality:

Dry granulation often results in a final product with better flow properties, improved density, and uniform size distribution. These qualities not only make the fertilizer more appealing to consumers but also ensure consistent application rates and nutrient delivery when the product is used in the field.

Conclusion:

The incorporation of dry granulation equipment in fertilizer pellet production offers numerous benefits, including cost and energy savings, product stability, ease of handling, and environmental advantages. By improving the efficiency and sustainability of the production process, dry granulation stands out as a key technology in modern fertilizer manufacturing, helping to meet the agricultural industry’s demand for high-quality, environmentally responsible fertilizer products. For dry granulation equipment buying, you can visit https://organicfertilizerproductionline.com/dry-granulation-equipment/